In the world of automotive engineering, fuel delivery systems play a crucial role in ensuring the efficient and reliable operation of internal combustion engines. One key component of these systems is the fuel pump, which is responsible for delivering fuel from the tank to the engine. In the case of mechanical fuel pumps, the question arises: does a mechanical fuel pump need a fuel pressure regulator? In this blog post, we will delve into the intricacies of mechanical fuel pumps and explore the necessity and benefits of incorporating a fuel pressure regulator into their design.

- Understanding Mechanical Fuel Pumps:

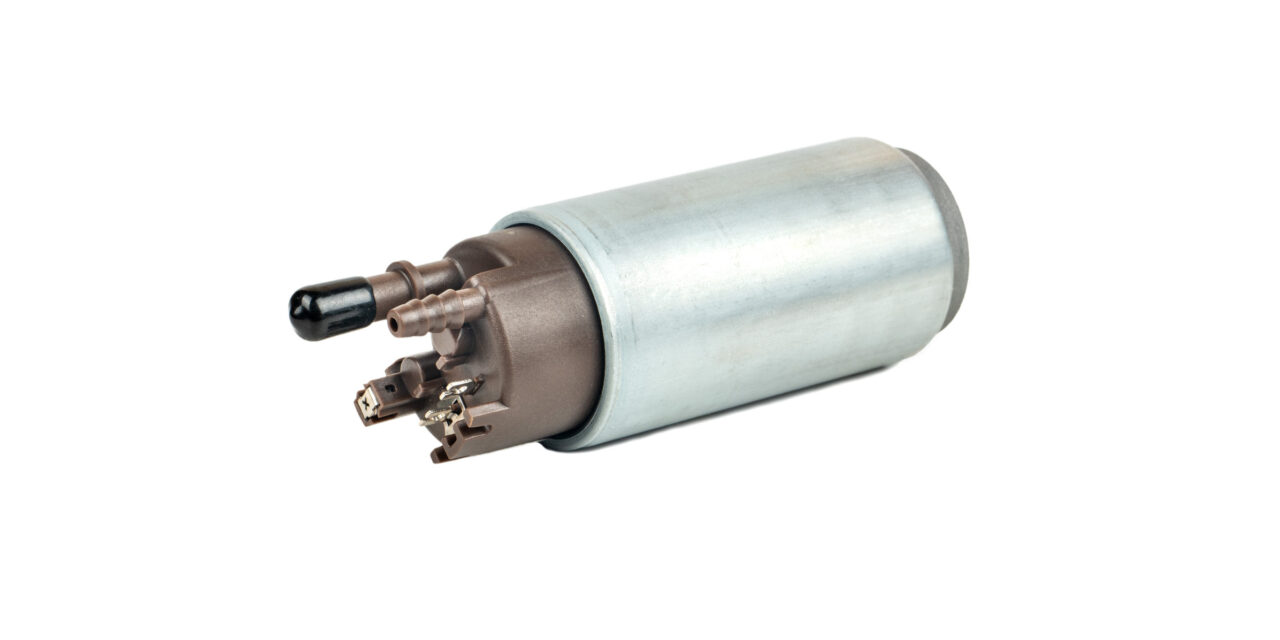

Mechanical fuel pumps have been a staple in automotive applications for decades. They are typically driven by the engine's camshaft or a separate eccentric shaft, utilizing mechanical motion to draw fuel from the tank and deliver it to the carburetor or fuel injectors. These pumps operate at a relatively constant pressure, which can vary depending on the engine's requirements. - The Role of Fuel Pressure Regulators:

While mechanical fuel pumps can deliver fuel at a consistent pressure, the fuel pressure regulator serves as a critical component in maintaining optimal fuel pressure throughout the system. The primary function of a fuel pressure regulator is to control and regulate the fuel pressure delivered to the carburetor or fuel injectors. By doing so, it ensures that the engine receives the correct amount of fuel under varying operating conditions. - Benefits of Fuel Pressure Regulators:

3.1. Fuel Efficiency: A fuel pressure regulator helps optimize fuel delivery, ensuring that the engine receives the right amount of fuel for combustion. This, in turn, improves fuel efficiency and reduces wastage, leading to cost savings for the vehicle owner.

3.2. Engine Performance: By maintaining a consistent fuel pressure, a fuel pressure regulator helps achieve optimal engine performance. It ensures that the fuel-air mixture is properly balanced, allowing the engine to operate at its peak efficiency and power output.

3.3. Durability and Reliability: Fuel pressure regulators also contribute to the longevity and reliability of the fuel delivery system. By preventing excessive fuel pressure, they protect the carburetor or fuel injectors from damage and potential leaks, extending their lifespan.

- Factors Influencing Fuel Pressure Regulation:

Several factors can influence the need for a fuel pressure regulator in a mechanical fuel pump system. These include the engine's power requirements, fuel system design, and the presence of additional components such as turbochargers or superchargers. It is essential to consider these factors when determining whether a fuel pressure regulator is necessary for a specific application.

Conclusion:

In conclusion, while mechanical fuel pumps are capable of delivering fuel without a fuel pressure regulator, incorporating one into the system offers numerous benefits. From optimizing fuel efficiency and engine performance to enhancing durability and reliability, a fuel pressure regulator plays a vital role in ensuring the smooth operation of mechanical fuel pump systems. By understanding the importance of fuel pressure regulation, automotive engineers can design more efficient and reliable fuel delivery systems for a wide range of applications.