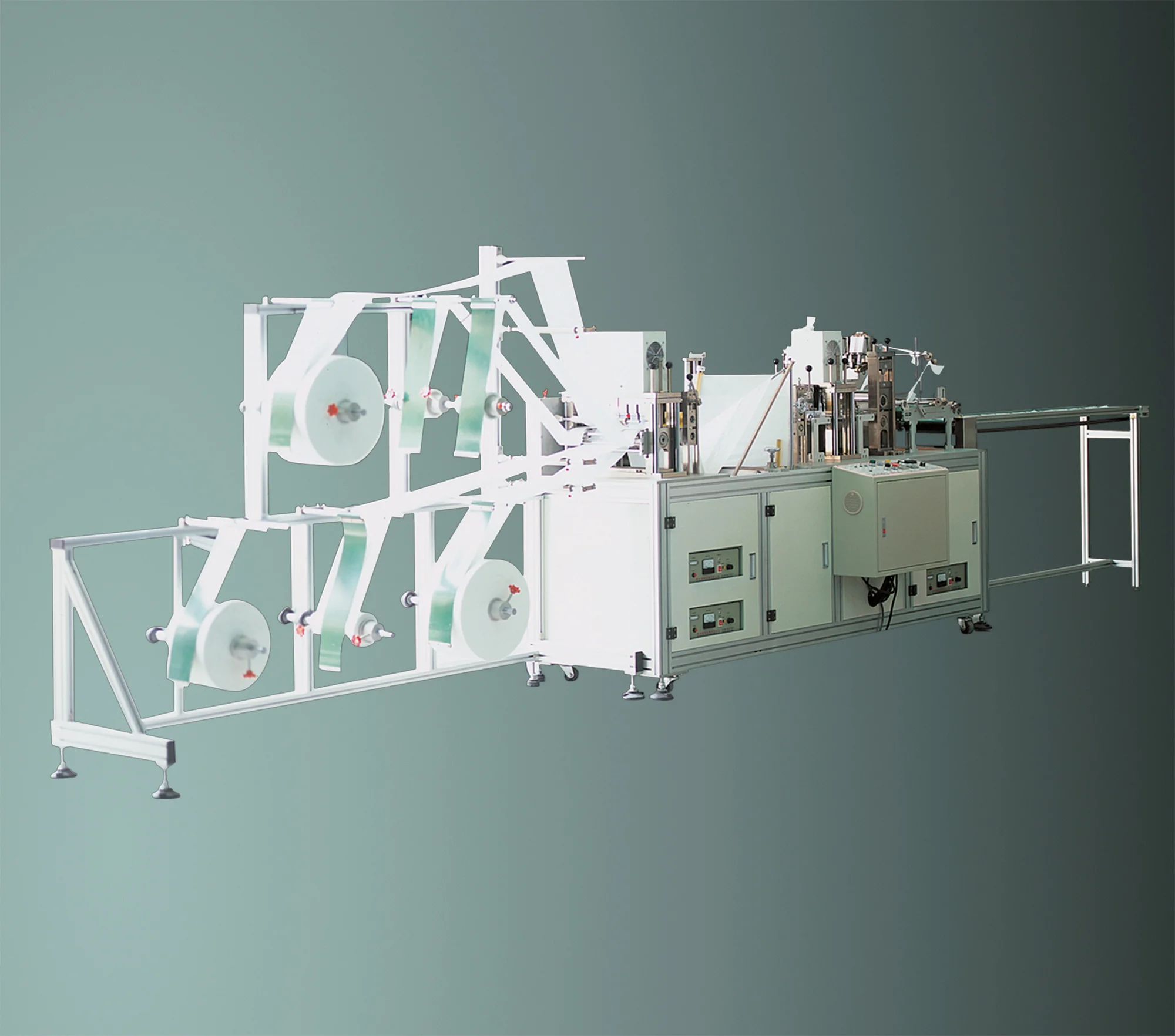

In the fast-growing PPE industry, maintaining stable and efficient production is critical. A folding mask machine, also known as an automatic mask making machine, plays a central role in modern mask manufacturing lines. Proper maintenance is essential not only for extending machine lifespan but also for ensuring consistent mask quality, reducing downtime, and maximizing return on investment.

As a professional manufacturer of automatic mask machines and non-woven PPE production equipment, Broadfair Automation Equipment Co., Ltd. provides reliable folding mask machines designed for high-speed, continuous operation. However, even the most advanced equipment requires systematic maintenance to achieve long-term performance.

(Broadfair Company Profile)

1. Daily Cleaning: The Foundation of Mask Machine Maintenance

Daily cleaning is the most basic yet most overlooked step in mask making machine maintenance. During high-speed production, non-woven fibers, dust, and elastic debris can accumulate quickly and affect machine accuracy.

Best practices include:

-

Cleaning machine surfaces, guide rails, rollers, and conveyors at the end of each shift

-

Removing fiber buildup around folding units and cutting stations

-

Wiping photoelectric sensors and ultrasonic welding areas to maintain detection accuracy

Regular cleaning improves machine stability, reduces material waste, and helps maintain consistent output quality—especially important for surgical and KN95 mask production.

2. Proper Lubrication for Smooth High-Speed Operation

A folding mask machine contains many moving components such as bearings, gears, chains, and linear guides. Without proper lubrication, friction increases, leading to premature wear and unplanned downtime.

Maintenance tips:

-

Use manufacturer-recommended lubricants for mask production equipment

-

Lubricate key moving parts weekly or according to production intensity

-

Avoid excessive lubrication, which can attract dust and contaminate non-woven materials

Well-lubricated components ensure smoother operation, lower noise levels, and longer service life of your automatic folding mask machine.

3. Sensor Calibration Ensures Precision and Product Consistency

Modern automatic mask manufacturing lines rely heavily on sensors for material positioning, folding accuracy, and cutting length. Sensor misalignment can result in inconsistent mask size, poor folding, or defective welding.

To maintain precision:

-

Clean optical and photoelectric sensors regularly

-

Check alignment after material changes or machine adjustments

-

Recalibrate sensors monthly or after long production cycles

Accurate sensors directly improve product consistency and help factories meet medical and industrial mask standards.

4. Ultrasonic Welding System Care Is Critical

The ultrasonic system is one of the most important parts of a folding mask machine. It directly affects mask strength, ear loop bonding, and filtration layer sealing.

Key maintenance points:

-

Keep ultrasonic horns and anvils clean and free of residue

-

Inspect wiring and connectors to avoid power instability

-

Monitor welding quality and adjust parameters when necessary

A well-maintained ultrasonic system reduces defect rates and ensures strong, reliable welds across high-volume production.

5. Pneumatic and Electrical System Maintenance

Folding mask machines depend on stable pneumatic pressure and electrical control systems.

Recommended actions:

-

Check air pressure regularly and drain water from air filters

-

Inspect pneumatic tubes for leaks

-

Ensure PLC control systems, touch screens, and emergency stops function properly

Stable pneumatic and electrical systems are essential for safe operation and uninterrupted production of disposable mask manufacturing equipment.

6. Establish a Preventive Maintenance Schedule

A structured preventive maintenance plan helps reduce unexpected breakdowns and extends machine lifespan.

| Maintenance Frequency | Key Tasks |

|---|---|

| Daily | Cleaning, visual inspection, sensor wiping |

| Weekly | Lubrication, belt and roller inspection |

| Monthly | Sensor calibration, electrical inspection |

| Annually | Deep inspection, part replacement, professional servicing |

Preventive maintenance is especially important for factories operating high-speed automatic mask machines 24/7.

7. Choose Reliable Equipment and Professional Technical Support

Founded in 2006, Broadfair Automation Equipment Co., Ltd. specializes in fully automatic mask machines, folding mask machines, and complete mask production lines. The company integrates R&D, manufacturing, and quality control, delivering stable and efficient automation solutions to customers worldwide.

(Learn more about Broadfair)

Broadfair’s equipment is designed with maintenance accessibility, durable components, and long-term operation in mind—helping manufacturers reduce operational risk and production costs.

Conclusion

Effective maintenance is the key to maximizing the performance of your folding mask machine and ensuring long-term production stability. Through regular cleaning, proper lubrication, sensor calibration, and structured preventive maintenance, manufacturers can significantly improve efficiency and reduce downtime.

By combining good maintenance practices with high-quality equipment from trusted suppliers like Broadfair Automation Equipment Co., Ltd., your factory can stay competitive in the global PPE market while delivering reliable, high-quality masks to customers worldwide.

Top Benefits of Using a Fully Automatic Folding Mask Machine in Your Factory

www.broadfairmachine.com

Broadfair Automation Equipment Co., Ltd.