In today’s increasingly polluted world, clean air and water are no longer taken for granted — they are carefully engineered through advanced filtration systems. At the heart of many of these systems lies a crucial component: chemical filter media. These specialized materials are designed to capture, neutralize, or transform harmful substances, playing a vital role in industrial air purification, water treatment, and even household filtration products.

As environmental standards continue to tighten worldwide, the demand for high-performance, sustainable filter materials has never been greater. Feierda, a professional company focused on the research, development, production, and sales of eco-friendly filter media, has emerged as a key player in this critical industry. In this article, we explore the most commonly used types of chemical filter media — from activated carbon to zeolite and beyond — and explain what makes each of them effective.

1. Activated Carbon: The Classic Workhorse

Activated carbon, also known as activated charcoal, is one of the most widely used filter media. It is made from organic materials like coconut shells, wood, or coal, which are activated through high-temperature processing to create a highly porous structure.

Key Features:

Extremely large surface area

Strong adsorption capacity for VOCs, odors, and chlorine

Effective in both air and water purification systems

Common Applications:

Indoor air purifiers

Drinking water filters

Industrial gas treatment

Why It Matters:

Activated carbon’s ability to adsorb a wide variety of contaminants makes it versatile and dependable. Feierda produces high-quality activated carbon media designed for optimized adsorption efficiency and environmental compliance.

2. Zeolite: Nature’s Molecular Sieve

Zeolite is a naturally occurring or synthetically produced aluminosilicate mineral known for its ion exchange and molecular sieving capabilities. Its crystalline structure allows it to trap molecules based on size and polarity.

Key Features:

High cation exchange capacity (CEC)

Selective adsorption of ammonia, heavy metals, and certain odors

Thermally stable and chemically inert

Common Applications:

Aquarium and wastewater filtration

Industrial gas separation

Indoor odor control

Why It Matters:

Zeolite’s selectivity makes it ideal for targeted filtration, especially in applications where removing specific ions or gases is essential. Feierda offers custom-formulated zeolite media tailored to various environmental needs.

3. Impregnated Activated Carbon: Enhanced Reactivity

Impregnated activated carbon is standard activated carbon that has been treated with chemicals to enhance its reactivity toward specific pollutants such as acid gases, mercury, and formaldehyde.

Key Features:

Reactive coating enables chemical bonding with target contaminants

Extended adsorption for corrosive or hazardous gases

High effectiveness in low-concentration environments

Common Applications:

Laboratory fume hoods

Chemical storage areas

Industrial emission control systems

Why It Matters:

Impregnated carbon allows for more advanced filtration in demanding settings. Feierda engineers and supplies customized impregnated carbon solutions for high-risk industrial and environmental applications.

4. Alumina-Based Media: Fluoride and Arsenic Removal

Activated alumina is a porous, granular form of aluminum oxide commonly used to remove fluoride, arsenic, and other contaminants from water. Its high surface area and reactive properties make it a specialized but powerful filter medium.

Key Features:

Selective fluoride adsorption

Stable in high-flow systems

Regenerable in some applications

Common Applications:

Drinking water treatment plants

Point-of-use water filters

Industrial wastewater remediation

Why It Matters:

With growing concerns over fluoride and heavy metal contamination, alumina-based media provide a reliable, targeted solution. Feierda develops alumina filtration products that meet global drinking water safety standards.

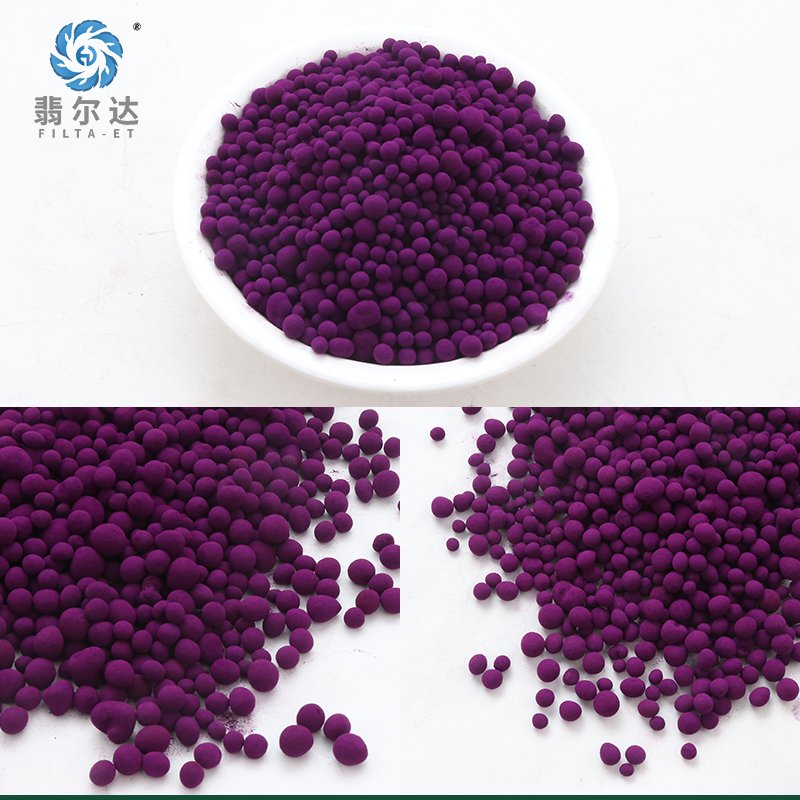

5. Hybrid and Composite Media: Tailored Performance

Hybrid filter media are designed by combining two or more materials — such as activated carbon with zeolite, or carbon with potassium permanganate — to deliver broader or more targeted filtration capabilities.

Key Features:

Multi-functional adsorption and chemical reaction

Custom formulations for complex environments

Greater lifespan and efficiency

Common Applications:

Commercial HVAC systems

Waste gas treatment in manufacturing

Why It Matters:

No single media fits every scenario. Hybrid media offer bespoke filtration for modern challenges. Feierda works closely with clients to develop composite filter materials that solve specific industrial and environmental problems.

Conclusion

As environmental challenges grow more complex, so too must our solutions. Understanding the characteristics, strengths, and limitations of each type of chemical filter media is key to designing effective and sustainable filtration systems.

Whether you need broad-spectrum air purification or specialized water treatment, Feierda is your trusted partner. With a strong commitment to innovation, quality, and environmental responsibility, Feierda delivers cutting-edge filter media that meet the evolving needs of industries and communities around the world.

How Dry Chemical Filter Media Works

www.filta-et.net

Feierda