Structural health monitoring (SHM) is undergoing one of the most important transitions in its history. Traditional sensing systems—based on point sensors or intermittent manual inspection—are gradually giving way to distributed optical fiber sensors (DOFS) capable of capturing continuous, real-time data across tens of kilometers of infrastructure. As critical assets age and safety requirements increase, distributed sensing is becoming more than an option; it is becoming an operational necessity.

Among the companies helping accelerate this transition is Shenzhen Mingsheng Electrical Co., Ltd., a provider of distributed fiber-sensing equipment and integrated monitoring solutions. Their product ecosystem spans distributed temperature sensing (DTS), distributed acoustic sensing (DAS), distributed vibration sensing (DVS), Brillouin-based technologies (BOTDA/BOTDR), fiber Bragg grating (FBG) systems, fluorescent fiber temperature sensors, and multiple types of temperature-sensing cables. This wide coverage allows them to tailor solutions for power grids, tunnels, pipelines, energy storage sites, tank farms, and more.

This article explores why distributed optical fiber sensors are shaping the future of SHM, the technologies behind them, and how companies like Shenzhen Mingsheng Electrical are enabling real-world deployment.

Why Distributed Optical Fiber Sensors Are Transforming SHM

1. Continuous, Real-Time Data Across Long Distances

Unlike traditional sensors placed at discrete points, distributed optical fiber sensors use the entire fiber as a sensing element. A single cable can continuously monitor temperatures, strain, vibrations, or acoustic signatures along its full length. This eliminates data blind spots and provides full visibility for large-scale structures such as:

Transmission lines

Subsea and onshore pipelines

Highways and tunnels

LNG storage tanks

Power stations

Industrial facilities

This spatial continuity is one of the strongest advantages of DOFS, especially when failures tend to start in localized regions that conventional sensors might miss.

2. High Durability and Electromagnetic Immunity

Optical fibers are inherently immune to electromagnetic interference, corrosion, lightning, and harsh weather. In high-voltage and high-temperature environments—such as transformer stations or battery energy storage facilities—this makes fiber-based sensors far more reliable than electronic sensors.

3. True Distributed Intelligence

Modern SHM is moving beyond data collection toward real-time decision support. Distributed sensing allows operators to:

Detect changes instantly

Identify the exact location of the anomaly

Predict faults before they escalate

Automate alarms and responses

This capability reduces downtime and improves operational efficiency.

Core Technologies Behind Distributed Optical Fiber Sensors

DTS (Distributed Temperature Sensing)

DTS uses Raman scattering to provide continuous temperature profiling along the fiber. It is widely used for:

Fire detection in cable tunnels or conveyor belts

Temperature monitoring in LNG tanks

Leakage detection in district heating pipelines

DAS (Distributed Acoustic Sensing)

DAS detects vibrations and acoustic signals using Rayleigh scattering. It transforms an ordinary optical fiber into thousands of virtual microphones. Applications include:

Intrusion detection

Pipeline leak or tapping detection

Traffic flow monitoring

Power cable monitoring

DVS (Distributed Vibration Sensing)

DVS focuses specifically on vibrational frequencies and is suitable for structural fatigue analysis or mechanical diagnostics in rotating machinery.

BOTDA/BOTDR

These Brillouin-based technologies measure strain and temperature with high precision over long distances. Ideal for:

Tunnel deformation monitoring

Bridge strain analysis

Slope stability monitoring

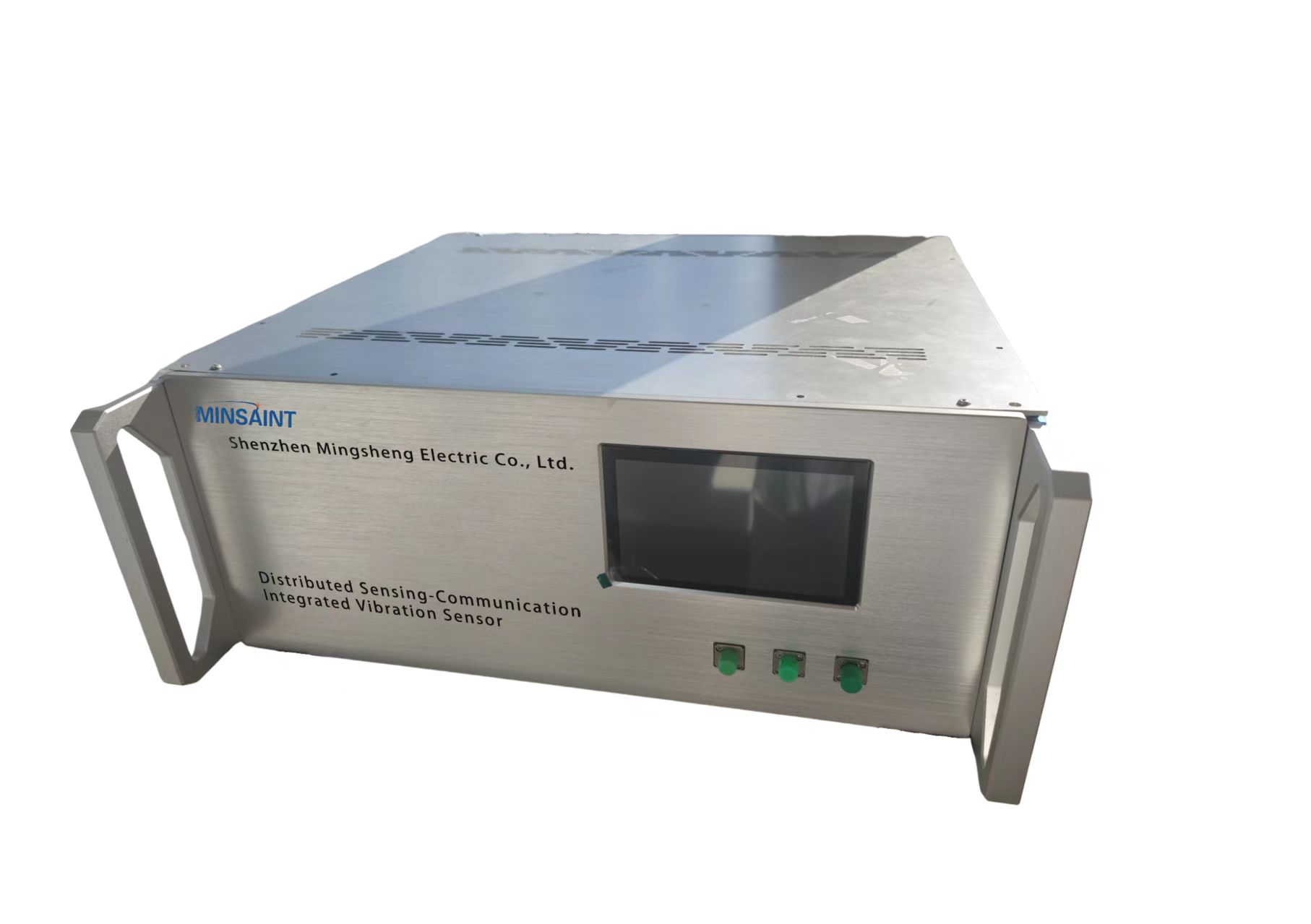

Shenzhen Mingsheng Electrical integrates these sensing technologies into advanced systems such as their distributed sensing & communication integrated sensor, which you can explore through their detailed product page here: distributed sensing & communication integrated sensor.

Real-World Application Scenarios

1. Lithium Battery Rack Fire Detection

As energy storage systems expand globally, fire hazards associated with lithium battery cells remain a major concern. Distributed fiber sensing enables:

Ultra-early thermal anomaly detection

Continuous monitoring inside dense battery racks

Real-time alerts for overheating or thermal runaway initiation

Shenzhen Mingsheng Electrical’s lithium battery rack detection system integrates DTS fibers directly into the racks, ensuring that even a subtle temperature rise is captured at the centimeter level.

2. Electric Power Online Monitoring

High-voltage electrical equipment requires reliable monitoring due to the high risk of insulation failure or overheating. Fiber sensing is ideal for:

Cable temperature tracking

Transformer winding hot-spot monitoring

Switchgear fire early-warning

With optical immunity and long-term stability, these systems significantly raise the safety level of power infrastructure.

3. Pipeline Safety Early Warning

Pipeline failures can result in major environmental and economic damage. Distributed sensing provides precise detection of:

Leaks

Ground movement

Third-party intrusion

Pressure-induced strain changes

The company’s pipeline early-warning solutions leverage DAS, DTS, and DVS technologies to capture acoustic patterns and temperature anomalies. Operators receive automated alerts with exact GPS-localized event positions.

4. LNG and Storage Tank Temperature Measurement

Large tanks require accurate vertical and horizontal temperature data to ensure safe operations. Fluorescent fiber temperature devices and DTS cables provide:

High-resolution temperature profiles

Corrosion-resistant long-term performance

Integration with tank farm control systems

These systems are widely used in petrochemical facilities and LNG storage bases.

5. Tunnel and Highway Monitoring

Distributed fiber sensors are increasingly implemented in highway tunnels, metro tunnels, and subsea tunnels for:

Real-time fire detection

Structural deformation monitoring

Vehicle flow estimation

Vibration analysis from passing traffic

Shenzhen Mingsheng’s solutions deliver both safety and operational insights.

6. Grain Silo Temperature Monitoring

Temperature rise in grain silos can lead to spoilage or combustion. Fiber-based temperature monitoring provides:

Continuous assessment of internal temperature distribution

Early detection of fermentation hotspots

Integration with silo automation systems

7. Ultra-Early Electrical Fire Detection

Many electrical fires begin with loose contacts, insulation degradation, or overheating cables. Fiber sensing provides:

Millisecond response to abnormal temperature increases

Non-intrusive installation

Long service life

This is valuable for commercial buildings, industrial plants, and data centers.

8. Synesthesia Technology Systems

Shenzhen Mingsheng Electrical also develops synesthesia systems combining temperature, vibration, and acoustic sensing into a unified platform. This hybrid approach enhances detection accuracy and reduces false alarms.

Advantages of Shenzhen Mingsheng Electrical Co., Ltd. Solutions

Integrated Product Ecosystem

Rather than offering isolated components, the company builds complete monitoring chains from sensors to control platforms. This includes:

Distributed optical fiber devices

Fiber current transformers

Fiber Bragg grating sensors

Fluorescent temperature sensing systems

Special-purpose temperature cables

This ensures compatibility and simplifies deployment.

Engineering Experience

The company has practical experience across diverse industries including energy, chemical processing, transport infrastructure, and public safety systems. Their solutions are adapted to real-world conditions such as vibration, humidity, installation constraints, and long-term maintenance needs.

Scalability and Customization

Whether monitoring a 10-meter battery cabinet or a 100-kilometer pipeline, the systems can be scaled and customized. This flexibility is essential as industries adopt digital transformation strategies.

The Future of Distributed Fiber Sensing

As industries shift toward predictive maintenance and autonomous monitoring, distributed fiber sensing will play a central role. Key trends include:

Integration with AI-driven analytics

Edge computing for faster response

Multi-parameter hybrid sensing

Cloud-based monitoring platforms

Smart industrial and smart city applications

Shenzhen Mingsheng Electrical’s continued focus on research and real-world deployment positions them as an influential contributor in this field.

Distributed optical fiber sensors are no longer emerging technology—they are becoming the backbone of modern structural and environmental monitoring. As infrastructures become more complex and safety requirements more stringent, the demand for continuous, real-time, high-precision monitoring will only continue to grow.

www.minsaint.com

Shenzhen Mingsheng Electrical Co ., Ltd. ( MINSAINT)