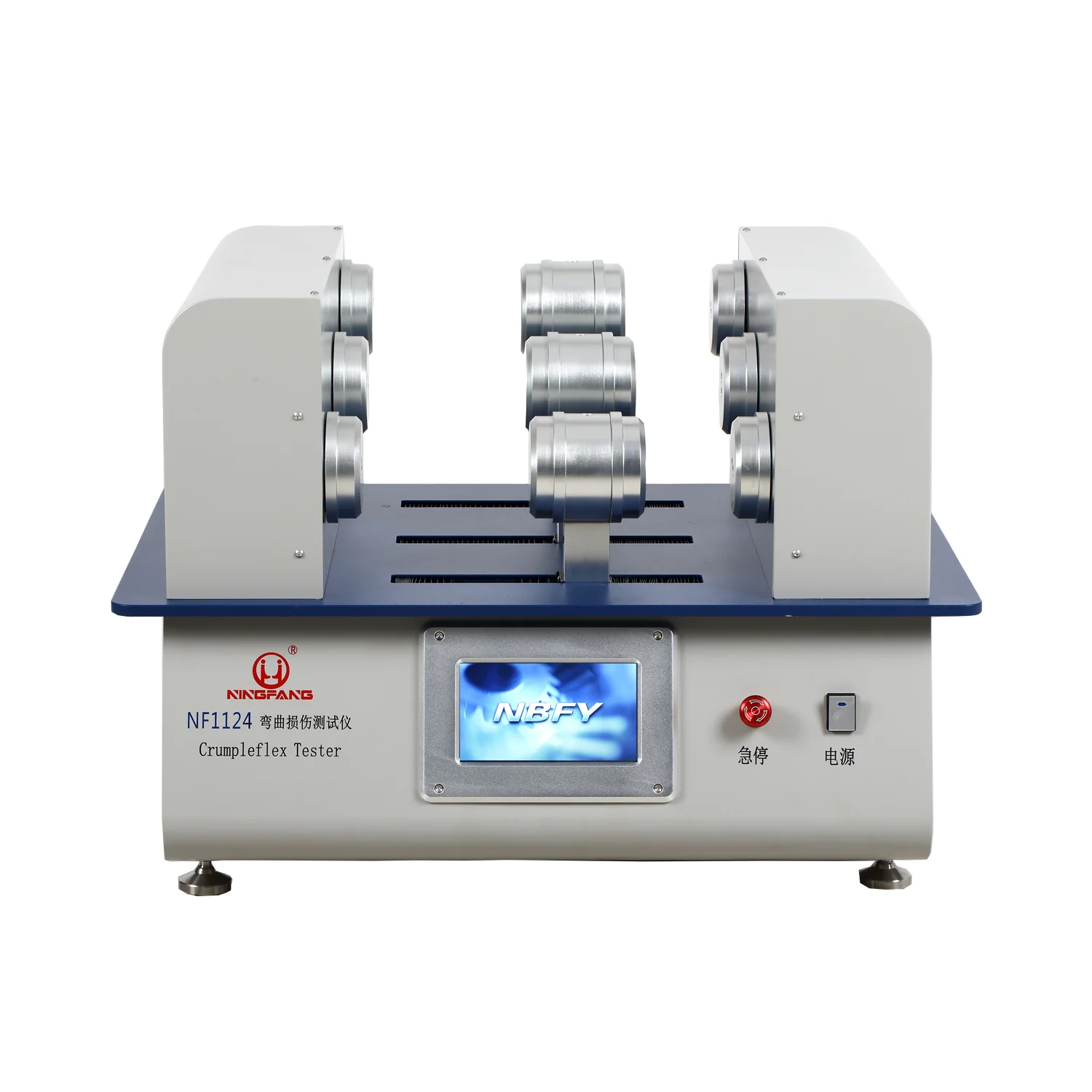

In the realm of materials science and engineering, accurate assessment of material strength is paramount to ensuring the safety, durability, and performance of various structures and products. Among the numerous testing methodologies, the Ningbo Textile Instrument Factory's bending damage tester has emerged as a versatile and reliable tool for evaluating the mechanical properties of materials.

Core Features of Bending Damage Testers

Precision and Accuracy

At the heart of any bending damage tester lies its precision and accuracy in measuring material deformation and failure under bending loads. Advanced sensors and data acquisition systems ensure that even minute changes in material behavior are captured, providing a comprehensive understanding of the material's strength characteristics.

Versatility

Bending damage testers are designed to accommodate a wide range of materials, from metals and alloys to plastics and composites. Their modular design allows for easy adaptation to different test configurations, making them indispensable in research and development, quality control, and educational settings.

User-Friendly Interface

Intuitive control panels and software interfaces facilitate seamless operation, even for users with minimal technical expertise. Real-time data visualization and reporting tools enable quick interpretation of test results, streamlining the decision-making process.

Applications in Material Strength Assessment

Metals and Alloys

In the automotive, aerospace, and construction industries, metals and alloys are subjected to extreme bending forces. Bending damage testers help evaluate their resistance to fatigue, creep, and brittle fracture, ensuring that they meet stringent safety standards.

1. Fatigue Testing: Assesses material durability under cyclic loading conditions.

2. Creep Testing: Measures deformation over time under constant stress.

3. Fracture Toughness Testing: Determines the energy required to propagate a crack.

Plastics and Polymers

Plastics and polymers are widely used in packaging, electronics, and medical devices. Bending damage testers are instrumental in evaluating their flexibility, impact resistance, and stress-strain behavior, which are crucial for product design and optimization.

1. Flexural Strength Testing: Measures the ability of materials to resist bending without breaking.

2. Impact Testing: Simulates real-world collisions to assess material toughness.

3. Stress-Strain Analysis: Provides insights into material behavior under various loading conditions.

Composites

Composite materials, consisting of two or more distinct components, offer exceptional strength-to-weight ratios and corrosion resistance. Bending damage testers are essential for validating the integrity of these materials in applications such as wind turbines, sporting goods, and aerospace structures.

1. Interlaminar Shear Strength Testing: Evaluates bond strength between layers.

2. Open-Hole Tensile Testing: Assesses the effect of holes on material strength.

3. Environmental Durability Testing: Examines material behavior under extreme temperatures, humidity, and other environmental factors.

Key Selling Points

Enhanced Reliability and Safety

By providing precise and repeatable test results, bending damage testers ensure that materials meet or exceed industry standards, reducing the risk of failures and enhancing overall product reliability.

Cost-Effective Solutions

Incorporating bending damage testers into the product development cycle can lead to significant cost savings by identifying weaknesses early on and enabling design optimizations.

Innovation and Research

For researchers and innovators, bending damage testers serve as powerful tools for exploring new materials, understanding material behavior under unprecedented conditions, and driving technological advancements.

Regulatory Compliance

In industries where regulatory compliance is crucial, bending damage testers offer a means to demonstrate adherence to safety standards and regulations, fostering trust and credibility among stakeholders.

Conclusion

In conclusion, Ningbo Textile Instrument Factory's bending damage testers play a pivotal role in the assessment of material strength across diverse industries. Their precision, versatility, and user-friendly features make them indispensable in ensuring the quality, safety, and performance of various structures and products. By leveraging the capabilities of bending damage testers, organizations can drive innovation, enhance product reliability, and maintain regulatory compliance, ultimately contributing to a safer and more sustainable world.

https://www.nbfyti.com/application-of-bending-damage-tester-in-material-strength-assessment.html

www.nbfyti.com

Ningbo Textile Instrument Factory