The role of the drive valve interlock system in industrial production cannot be ignored. As a key device to ensure operational safety, it can effectively prevent safety accidents caused by misoperation or equipment failure. For enterprises, choosing a suitable drive valve interlock system should not only focus on its performance but also carefully evaluate its price and key factors affecting the cost. This article will comprehensively analyze the price structure and influencing factors of the drive valve interlock system to help you make more informed decisions during the procurement process.

1. Basic functions of the drive valve interlock system

The drive valve interlock system is a device that interlocks and controls valves by physical or mechanical means. Its main functions include:

Prevent misoperation: ensure that the operation sequence meets the design specifications and avoids human errors.

Ensure equipment safety: reduce equipment damage caused by excessive pressure, abnormal temperature, etc.

Optimize production efficiency: improve production continuity through standardized operating procedures.

Compliance requirements: comply with relevant safety standards and regulations to reduce corporate compliance risks.

These functions directly affect the design complexity and manufacturing cost of the system, so they have a greater impact on the price.

2. The price composition of the drive valve interlock system

The price of the drive valve interlock system is usually composed of the following parts:

Core material cost: The metals, alloys and other corrosion-resistant materials required for system manufacturing are the main part of the cost. For example, stainless steel and high-strength aluminum alloys are widely used to manufacture high-end systems due to their durability and corrosion resistance.

Design and R&D costs: An efficient drive valve interlock system requires customized design in combination with specific working conditions, including software and hardware development. Complex designs will increase R&D investment, which will be reflected in the price.

Manufacturing costs: Modern production processes and high-precision processing equipment are important guarantees to ensure product quality. At the same time, complex processing processes and strict quality inspections will also increase manufacturing costs.

3. Key factors affecting prices

System complexity: Depending on the complexity of the application scenario, the drive valve interlock system may require additional sensors, control modules, and communication equipment. Complex system design will obviously bring higher costs.

Material selection: Different working environments have special requirements for materials. For example, systems used in highly corrosive or high-temperature and high-pressure environments need to select higher-specification materials, which will significantly increase the price.

Brand and technical level: Well-known brands are usually sold at higher prices due to their reliability and technical advantages. However, their products tend to undergo more rigorous testing and provide more complete technical support.

Market demand: The market supply and demand relationship has a direct impact on prices. When demand is high, prices may rise; when supply exceeds demand, prices may fall.

Customized demand: If the system needs to be customized for special working conditions, such as adding additional functions or adapting to specific equipment, the cost of customized design and production will increase significantly.

Geographical factors: The economic level, labor costs and logistics costs of the production and installation sites will also affect the overall quotation. For example, the transportation and tariff costs of imported systems may significantly increase their total cost.

4. How to balance price and performance

When purchasing a drive valve interlock system, price is not the only consideration. Here are a few suggestions to help companies find a balance between performance and price:

Clarify the needs: Clarify the system's usage scenarios and functional requirements before purchasing to avoid increasing the budget due to unnecessary high-end configurations.

Multi-party comparison: Compare the products of multiple suppliers, focusing on cost-effectiveness rather than simply pursuing low prices.

Pay attention to after-sales service: High-quality after-sales service can reduce maintenance costs in long-term use and should be taken into consideration when purchasing.

Evaluate long-term benefits: High-quality systems usually have a higher initial cost, but they have a long service life and can reduce operating risks and maintenance costs in the long run.

The price of a drive valve interlock system is affected by many factors, including materials, design, manufacturing, market, and region. For enterprises, choosing a product that can meet demand and control costs is a key consideration in the procurement process. In actual procurement, it is recommended that enterprises fully communicate with suppliers on the basis of a comprehensive evaluation of system functions, brand reputation, and after-sales service, clarify price composition and performance parameters, and ensure that they obtain cost-effective products. Through reasonable selection, the drive valve interlock system can not only improve the safety and efficiency of industrial production but also create greater economic benefits for enterprises.

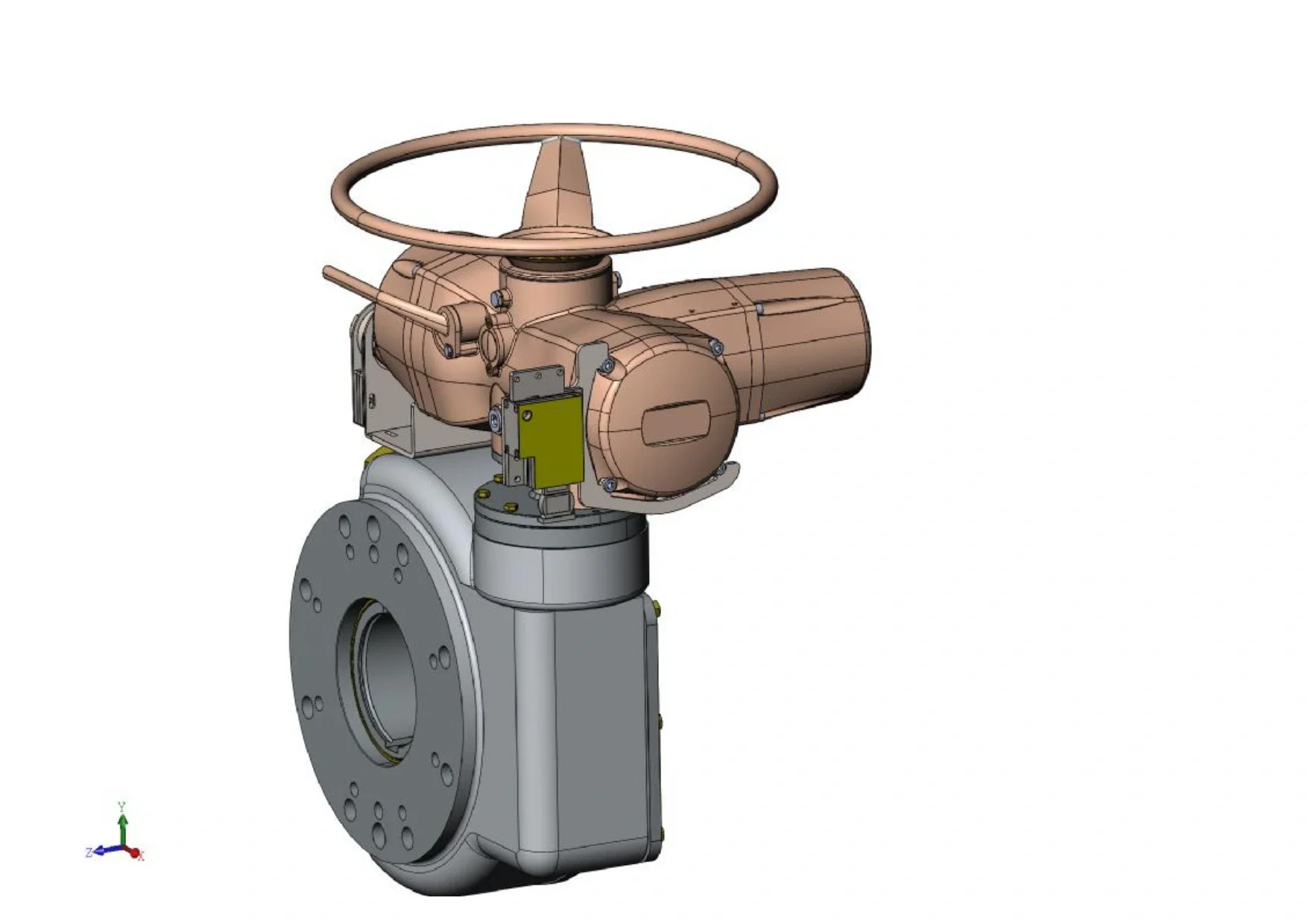

As a leading drive valve interlock company, we are well aware of the market's high requirements for safety, reliability, and automation. Our products not only follow international standards to ensure high quality and stability but also provide customized solutions according to customer needs. Whether facing complex industrial environments or specific application scenarios, our drive valve interlock system can efficiently and accurately control valve operation to ensure the safety and smoothness of the production process. Through advanced design concepts and innovative technologies, we are committed to providing customers with the most cost-effective products to help them achieve more efficient and safer production operations. At the same time, we also provide professional installation and maintenance services to ensure the long-term stability of the system and bring continuous value to customers.

www.nudango.com

Shanghai Nudango Safety Equipment Co., Ltd.