On-Site Flange Repair for a Fortune 500 Chemical Equipment Manufacturer – Using the FI26E Flange Facing Machine

Recently, the MT Portable Machine team was called to the site of Tianhua Institute (Nanjing) Intelligent Manufacturing Co., Ltd., a subsidiary of Sinochem Holdings Corporation Ltd. – one of China’s leading state-owned enterprises and a Fortune Global 500 company. Specializing in pressure vessel equipment and chemical plant fabrication, the client is known for its uncompromising standards in product quality and compliance with strict ASME specifications.

The service request involved the urgent repair of a damaged 650 mm raised-face flange sealing surface on a large pressure vessel. In chemical equipment manufacturing, even minor flange surface defects can lead to sealing failure, process leaks, or costly shutdowns. Given the client’s production schedule, the MT Portable Machine team mobilized immediately, arriving on-site within hours to provide a precision in-situ machining solution.

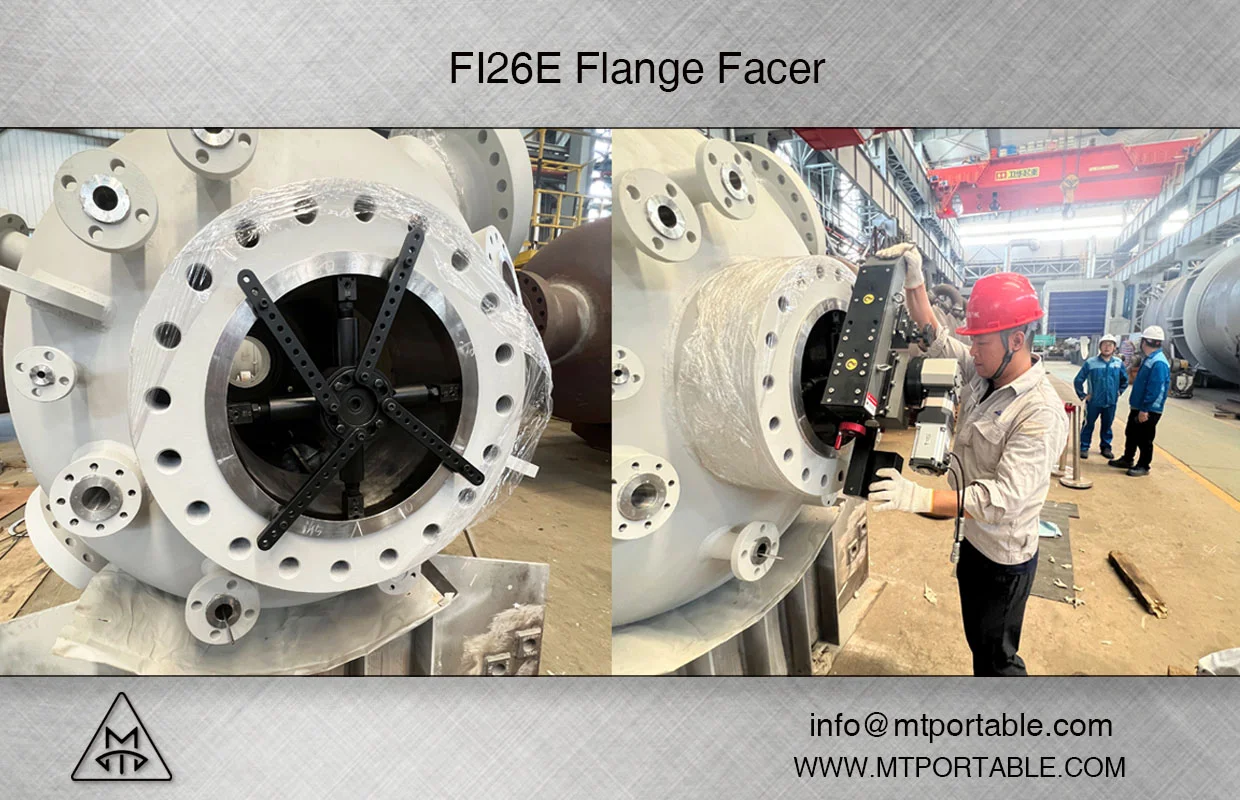

For this repair, we deployed our flagship FI26E Flange Facing Machine, an internally mounted, servo-driven unit with a facing range of 120 mm to 700 mm. The FI26E is widely regarded as the most advanced flange facer in its class, building on the proven MM610i platform but upgraded with a reinforced main spindle for greater rigidity and stability. This allows the machine to maintain tight tolerances and deliver a gramophone finish that fully complies with ASME B16.5 and B16.47 standards.

Once on site, our technicians quickly mounted the FI26E using its micro-adjustable jaw base system, ensuring perfect concentricity within minutes. The high-precision NSK bearings and “V” linear guideway system enabled exceptionally smooth feed motion, while the Panasonic servo motor maintained a constant cutting speed under load. Working with two selectable continuous feed rates, our team restored the sealing surface to a perfectly flat, concentric finish, eliminating deep corrosion marks and machining a precise spiral groove pattern to enhance gasket seating.

The entire repair process was completed in a single shift, with zero need to disassemble the vessel or transport it to a workshop. This not only minimized downtime but also saved the client significant logistics and labor costs. The FI26E’s compact, modular design made it easy to operate in the confined space of the chemical plant, and its capability to handle flange diameters up to 700 mm provided the flexibility needed for future maintenance tasks.

This successful intervention once again demonstrated MT Portable Machine’s core strengths – rapid response, on-site machining expertise, and precision engineering. Our ability to quickly deploy the right equipment and skilled technicians ensures that clients in demanding industries like chemical manufacturing can maintain their operational schedules without compromising safety or quality.

If you are facing similar flange damage or sealing surface issues, contact the MT Portable Machine technical team today to receive the latest product specifications and tailored on-site machining solutions at info@mtportable.com

www.mtportable.com

Jichuang Machinery Manufacturing Wuxi Co.,Ltd