In the world of plastic manufacturing, rotomolding (rotational molding) has become a preferred method for producing durable, high-quality products across various industries. The use of OEM rotomold molds can significantly enhance production efficiency while ensuring consistent product quality. By leveraging precision engineering and customized designs, manufacturers can optimize their processes and meet stringent industry standards.

This article explores the benefits of OEM rotomold molds, highlighting their impact on efficiency and quality, with insights from XINGHUI MOLD, a leading Chinese manufacturer specializing in rotomolding, vacuum forming, blow molding, foam molds, and custom rotationally molded products.

Understanding OEM Rotomold Molds

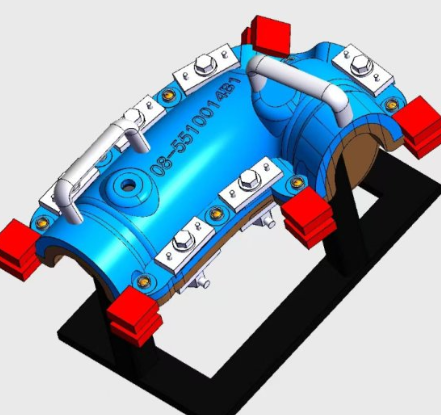

OEM (Original Equipment Manufacturer) rotomold molds are custom-designed molds produced specifically for a client’s product specifications. They serve as the foundation for rotomolding production, defining the shape, size, and surface features of the finished product.

Key characteristics of OEM rotomold molds include:

-

Precision engineering to achieve exact dimensions and design specifications

-

Durable construction to withstand repeated heating and cooling cycles

-

Versatility to accommodate a wide range of plastics and product types

By tailoring molds to specific production requirements, OEM solutions reduce waste, minimize rework, and ensure uniformity across batches.

Enhancing Production Efficiency

1. Faster Production Cycles

High-quality OEM rotomold molds are designed for optimal heat transfer and uniform wall thickness. This allows products to freeze and cure more quickly, reducing cycle times and increasing output.

2. Reduced Material Waste

Precision molds help eliminate excess material use by maintaining accurate dimensions and wall thickness. Consistent material usage translates into cost savings and less environmental impact.

3. Simplified Post-Processing

Accurate molds reduce the need for trimming, sanding, or finishing operations. This streamlines the production workflow, allowing teams to focus on assembly and packaging rather than corrective work.

4. Minimized Machine Downtime

Durable OEM molds withstand repeated use without warping or degrading. Fewer mold failures mean less downtime, higher throughput, and more predictable production schedules.

Ensuring Consistent Product Quality

Precision and Accuracy

OEM rotomold molds are engineered to exact specifications, ensuring that each product meets dimensional and structural requirements. This consistency is critical for products like automotive parts, industrial containers, and outdoor equipment.

Surface Finish and Aesthetics

High-quality molds produce smooth, defect-free surfaces, reducing imperfections such as uneven textures or weld lines. This improves both the functional performance and visual appeal of the product.

Customization for Industry-Specific Needs

Different industries have specific requirements:

-

Outdoor furniture and recreational equipment: UV resistance and ergonomic designs

-

Kayaks and canoes: Hydrodynamic shapes and impact resistance

-

Industrial tanks and containers: Thick walls for chemical or mechanical durability

-

Automotive parts: Tight tolerances and precise dimensions

OEM molds allow manufacturers to meet these specialized requirements consistently.

XINGHUI MOLD: Expertise in OEM Rotomold Solutions

XINGHUI MOLD is one of China’s leading manufacturers of rotomold molds, blow molds, vacuum forming molds, foam molds, and custom rotationally molded products. Their products serve a diverse range of industries, including outdoor furniture, kayaks, industrial tanks, automotive components, and custom-designed rotomold items.

XINGHUI MOLD provides:

-

End-to-end mold design and manufacturing based on client specifications

-

High-precision engineering to ensure consistent product quality

-

Durable molds capable of sustaining long production cycles

-

Industry-specific customization for outdoor, industrial, and automotive applications

By leveraging their expertise, manufacturers can optimize production efficiency and achieve superior product quality, giving them a competitive edge in both domestic and international markets.

Advantages of OEM Rotomold Molds

-

Improved Production Efficiency: Faster cycles, less material waste, and minimal post-processing.

-

Consistent Quality: Precision molds ensure uniform dimensions, strength, and surface finish.

-

Durability and Longevity: High-quality molds withstand repeated production without degrading.

-

Industry-Specific Customization: Tailored molds meet unique functional and aesthetic requirements.

-

Cost Savings: Reduced waste, fewer defects, and streamlined processes lower overall production costs.

Conclusion

OEM rotomold molds play a pivotal role in modern plastic manufacturing. By delivering precision, durability, and customization, they help manufacturers increase efficiency, reduce waste, and consistently produce high-quality products.

With their extensive experience in rotomold, blow mold, vacuum forming, and foam mold production, XINGHUI MOLD provides reliable OEM solutions for industries ranging from outdoor recreation and industrial storage to automotive and custom-designed products. By partnering with a trusted mold manufacturer, businesses can achieve optimized production workflows, superior product performance, and long-term operational success.

www.xinghuimould.com

Ningbo Xinghui Rotational Molding Technology Co., Ltd.