In the apparel industry, product designs are evolving rapidly, and consumers' pursuit of personalization and quality continues to rise. Traditional basic styles are no longer sufficient to meet market demand. More and more brands, designers, and e-commerce companies are beginning to question whether complex garments can be mass-produced. Is there a manufacturer that can meet these complex demands while maintaining stable production efficiency and high-quality delivery?

The answer is yes. As a professional processing factory specializing in mid-to-high-end custom apparel, we have years of experience and strong capabilities. We can mass-produce complex garments and customize them with various prints and special finishes to meet customer needs, making us a unique competitor in the market. This article will explain from multiple perspectives why we have become a leader in the field of complex garment processing.

1. What are "complex" garments?

Before we begin, we need to clarify the specific aspects of "complex" garments. Generally speaking, the following types of garments are considered more complex:

Multiple fabric splicing and combinations of different materials

Advanced printing techniques (such as water-based slurry printing, adhesive printing, digital printing, hot stamping, flocking printing, etc.)

Highly complex embroidery (hand embroidery, machine embroidery, bead embroidery, sequin embroidery, etc.)

Three-dimensional tailoring and structural design

Handmade embellishments and custom accessories (such as hand beading, metal embellishments, leather inlays, etc.)

Specialized washing or dyeing techniques (enzyme washing, distressing, cloud dyeing, tie-dyeing, etc.)

Multi-process and complex processes (such as multiple printing and dyeing, multi-layered sewing, and complex lining treatments)

These garments are not only intricately designed but also place extremely high demands on processing technology, equipment support, production coordination, and quality control. Consequently, most processing plants in the market struggle to handle these complex processes in mass production.

2. What advantages do we have that enable us to process garments with complex processes?

2.1 Deep industry experience and a professional team

With over 15 years of experience in garment processing, we have served numerous renowned domestic and international brands and are familiar with the process characteristics and key implementation points for various complex styles. Our technical team, comprised of experienced pattern makers, sample makers, and process engineers, can quickly understand the designer's intent and accurately translate creative proposals.

2.2 Full-Process Production Capabilities, Supporting Multiple Processes and Customization

We offer comprehensive capabilities, from sample making, pattern making, cutting, sewing, finishing, packaging, and shipping, with particular advantages in the following areas:

Printing: We support over ten printing methods, including water-based slurry, adhesive, heat transfer, digital direct printing, hot stamping, foaming, luminous, flocking, and glitter.

Embroidery: We possess advanced multi-head computerized embroidery equipment, capable of complex patterns, 3D embroidery, and sequin embroidery.

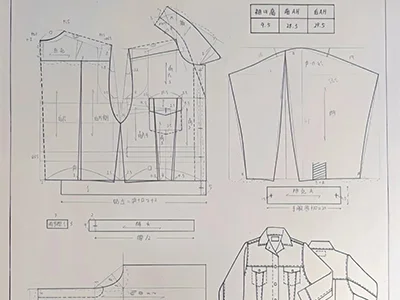

3D Cutting and Pattern Making: We have a team of professional pattern makers, supporting custom cuts and high-end customization.

Washing and Dyeing: Our experienced partner washing plant can achieve special effects such as enzyme washing, silicone oil washing, and stonewashing.

Accessories and Detailing: We can customize various accessories and decorations, including metal buckles, zippers, buttons, beads, and labels, to meet customer needs. 2.3 Strong Capacity for Large-Scale Delivery, Ensuring Quality and Efficiency

Many manufacturers can produce complex designs during proofing, but once they enter mass production, insufficient equipment and disorganized management often lead to quality fluctuations and delivery delays. We excel in mass production of garments with complex processes:

We have a standardized production workshop covering over 3,000 square meters;

We have implemented an ERP system and MES intelligent management to ensure smooth coordination of all processes;

We have dedicated QC specialists stationed at each stage to fully guarantee delivery quality;

Each large-scale product has a dedicated production SOP, detailing every process step.

3. Why do customers choose us to produce complex garments?

3.1 Solving Process Pain Points Small Factories Can't Achieve

Customers have reported that other factories were unable to perform the complex printing and washing processes, ultimately forcing them to abandon their original designs. Since taking over, we have successfully achieved a seamless combination of three printing steps, one flocking step, and an enzyme wash, earning high praise from our customers. 3.2 Save Time and Communication Costs

For complex craft projects, we provide one-stop service. Clients no longer need to search for separate printing, embroidery, and washing facilities. We handle everything in-house, significantly improving efficiency and stability.

3.3 Flexible Customization and Prototyping Support

We welcome small-batch prototypes, with a minimum order of 50 pieces, to meet the initial testing needs of designers and niche brands. We also support fast repeat orders and large-scale production, with an annual production capacity of over 500,000 pieces. IV. Real Customer Case Studies: Easily Handle Complex Crafts

Case 1: European and American Designer Brand Collaboration – Intricate Embroidery and Tailoring

Technology Requirements: 3D Pattern + 3D Chest Embroidery + Metal Chain Decoration at Hem

Fabric Combination: Silk + Imitation Leather Splicing

Processing Difficulties: Symmetrical Cutting and High-Precision Positioning

Results: Samples Passed First Review, Customers Placed Repeat Orders Three Times, Cumulative Orders of 8,000

Case 2: Domestic Trendy Brand Summer T-Shirt Series – Multiple Print Overlays

Technology Requirements: Four-Color Paste Printing + Luminous Flocking + Silicone Oil Soft Washing

Fabric Type: 260g Pure Cot

www.ncnewspring.com

NANCHANG NEWSPRING GARMENT MANUFACTURE CO.LTD.